P2X

Shaping the post-fossil age for plastics and fuels

How can volatile electricity be stored permanently? Power-to-X technologies are among the best answers to this question. But they offer additional possibilities because they turn electricity into "more": In the third project phase, P2X is increasingly focussing on eFuels.

Renewable energy is replacing fossil resources as we move towards climate neutrality. But the generation of electricity from sunlight and wind involves fluctuations. While a lot of electricity is generated at the peak of summer and in stormy periods, the situation is less favourable at night or in winter. Yet energy is always needed and long-term and flexible storage options are required. Power-to-X technologies, which are being researched by the Kopernikus project P2X, can provide such storage options. Furthermore, sustainable Power-to-X products can replace current climate-damaging fossil products.

The spectrum was broad during the first two project stages: P2X examined various technologies for producing hydrogen, fuels, plastics and chemical base materials based on electricity. The researchers have further advanced the production steps into complete value chains.

Additionally, P2X has developed a roadmap. It is monitoring the development of the various P2X technologies and evaluating them in terms of ecological, economic and social sustainability criteria. The findings will be incorporated into the further development of P2X technologies. Anyone interested can download all four previous versions of the roadmap at the bottom of this page.

In the final third phase, the project is focussing on synthetically produced aviation fuel (eKerosene). The general aim is to realise industrial use through further scaling. The "bridge" for the latter are demonstration projects.

Focus: aviation fuel, site analysis, capacity building

Aviation cannot be directly electrified, particularly not for medium and long-haul flights. That is why scientific consensus recognizes that aviation is predestined for the use of sustainable fuels. This is reflected in the German Federal Emissions Control Act, which provides for a mandatory blending quota of sustainable aviation fuel from 2026. EU legislation provides for this from 2025. This is intended to make air travel less harmful to the climate. The focus set for the final phase three of the P2X project - the production of eKerosene and chemical utilisation of the by-products - therefore matches the legally imposed blending quotas.

P2Fuels, which is the core P2X demonstration project, addresses this issue. It is planned to build a refinery at Industriepark Höchst in Frankfurt am Main that can process power-to-liquid crude (synthetic crude oil) into specification conforming aviation fuel, which can then be traded. Accompanying analyses ensure that the fuel complies with norms and meets the stringent aviation requirements. This synthetic aviation fuel is derived from CO2 By-products such as naphtha are also considered to evaluate further sustainable products with added value and consequently increase the plant’s economic efficiency. Yet the optimisations also address another point, specifically the engine combustion chambers. For this purpose, the researchers are investigating whether NOx emissions can be reduced. They are also monitoring regulatory issues in all of these activities.

Among additional tasks that P2X sets for itself during the third project stage are: analysing the life cycle of the pilot plant, assessing the availability of critical raw materials, taking environmental impacts into account and examining the suitability of various plant sites. The existing educational programme for PtX is also being expanded in order to create a transfer of knowledge, particularly for learners and students. Further related aspects are complemented by two satellite projects, which essentially develop and demonstrate aspects based on previous P2X successes.

Achievements to date

Electrolysis divides the molecule water (H2O) into oxygen (O2) and hydrogen (H2). P2X has investigated electrolysers that require less iridium than before. The precious metal is extremely rare, and supplies are limited. The researchers have succeeded in reducing the amount of iridium in hydrogen electrolysis by a factor of ten - while maintaining the same output. This enables a significantly more cost-efficient production of hydrogen electrolysers.

Synthesis gas is a mixture of hydrogen and carbon monoxide. P2X utilizes it to produce fuels and raw materials for the chemical industry. Depending on the desired product, though, a different ratio of hydrogen to carbon monoxide is required. The project has developed a process that converts water and CO2 into synthesis gas in just one step using electricity from renewable sources (solar, wind). This so-called high-temperature co-electrolysis takes place at 800 degrees Celsius. The special feature of the P2X system is that it can produce synthesis gas with different mixing ratios of hydrogen and carbon monoxide.

P2X has commissioned the world's first integrated plant that produces fuel from air and renewable electricity in four steps. A container-sized prototype produced around ten litres of fuel per day. In 2022, the successor model had already the capacity of 200 litres per day.

Please understand that this short explainer video is unfortunately only available in German.

Pure hydrogen can only be transported under high pressure or at extremely low temperatures. Both methods are complex and expensive. Less energy-intensive is the use of liquid organic hydrogen carriers (LOHC). The consistency and properties are similar to existing fuels. This would allow utilization of the existing infrastructure for transport and distribution. To release the hydrogen from the carrier liquid, so-called dehydrogenation catalysts are required. P2X has succeeded in developing a catalyst that can release large quantities of bound hydrogen whilst not requiring large quantities of precious metals. The P2X catalyst was such a success that it is already available on the market under the name "EleMax D101".

Oxymethylene ethers - OME for short - are low-emission fuels and can be used in the production of plastics. P2X researchers have produced them from carbon monoxide, hydrogen and methanol. So far, expensive catalysts coated with rare precious metals were required. The project has now developed ways of using catalysts that do not require precious metals and allow for a more efficient conversion.

Project background in detail

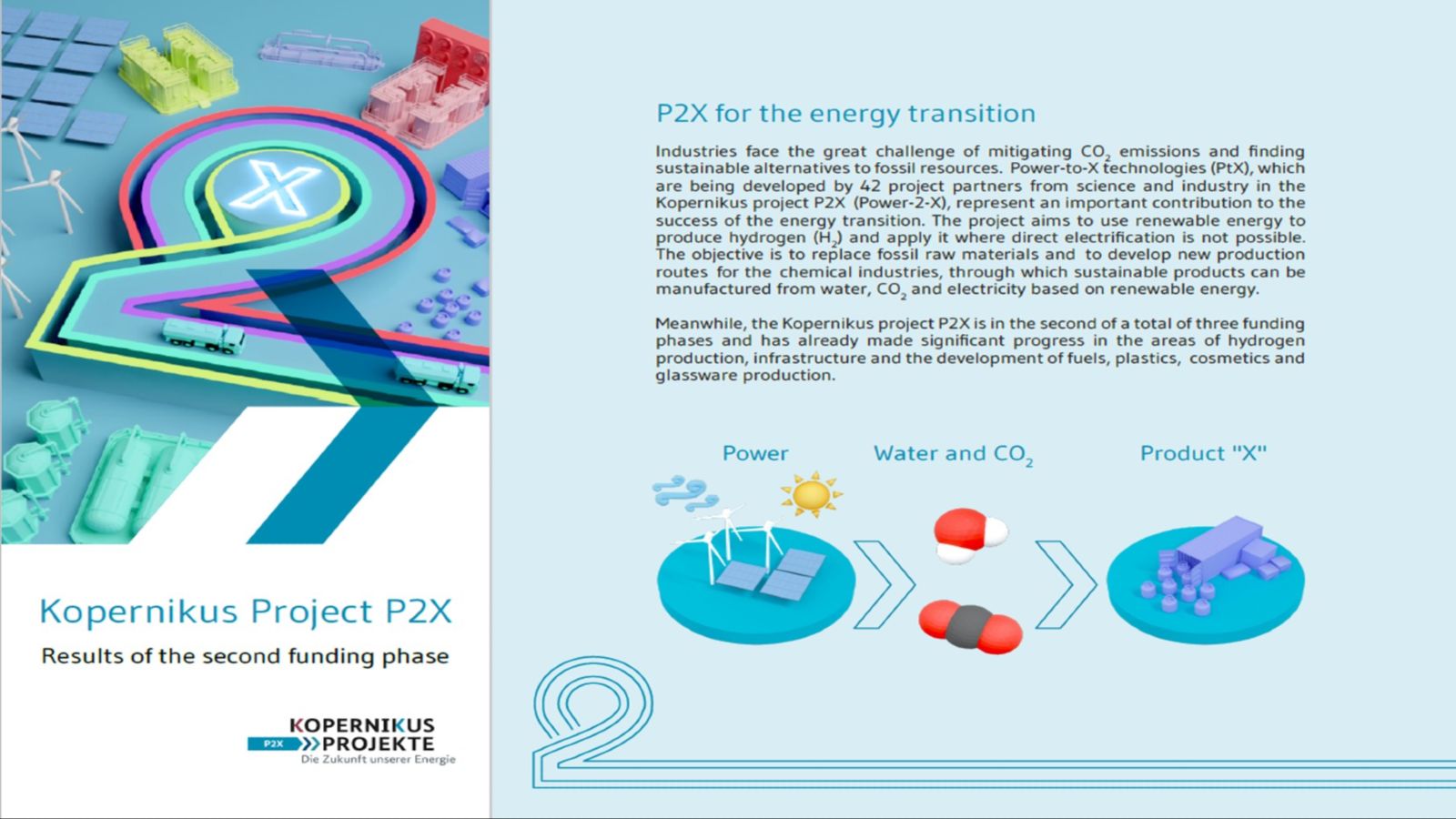

Using renewable electricity as power to generate sustainable products (X) is what scientists call Power-to-X. Experts like to use the abbreviation "PtX". Power-to-gas, for example, results in gaseous substances such as hydrogen or methane. Power-to-chemicals creates chemical raw materials that are further processed industrially. The product of power-to-fuels is climate-friendly fuel. Carbon dioxide (CO2) extracted from the air or from exhaust gases is used here. This means that a significant overall reduction in emissions is achieved when combusting the fuel.

What exactly do Power-to-X technologies contribute to the energy transition? And even more: why are they indispensable? The most important arguments are summarized in the following and provide a quick overview.

- In their role as chemical energy storage systems, PtX technologies enable flexibility by augmenting volatile renewable energies.

- They can be deployed where direct electrification is not possible or not economical (heavy goods transport, sea and air transport, chemical industry, steel, and glass production).

- PtX technologies also help to replace fossil raw materials and energy sources in the production of fuels and other commodities, thereby reducing CO2 emissions.

In the first two project phases, hydrogen, as one of the most relevant Ppower-to-X products for the energy transition, was repeatedly a focus of P2X. The following questions, along with others, were explored:

- How to reduce costs and accelerate upscaling by lowering the amount of the rare metal iridium without losing efficiency?

- Which potential applications in the (chemical) industry for hydrogen, such as conversion into polymer components, are particularly promising?

- What must be taken into account if hydrogen were to be considered as a fuel in the mobility sector, for example at petrol stations?

- How is it possible to fuel industrial furnaces economically with hydrogen?

- To which chemical compounds can hydrogen be bound to transport it more easily and safely?

The answers can be found in the project results, some of which will be adopted and pursued further by other projects.

Successes and results from the initial phases of P2X do not stop there, but rather form a starting point for further developments and follow-up research in several areas. This applies to the two current satellites, but also to other projects such as

- IRIDIOS in H2Giga in the hydrogen flagship projects: The researchers are aiming to scale up the catalyst developed as part of P2X with reduced iridium loading (from phase one, tested in phase two) into an electrolyser for PEM electrolysis.

- 350 bar LOHC hydrogen refuelling station (phase two): Design of components such as H2 compressors, H2 storage tanks and H2 purification units as well as a hydrogen refuelling station in Erlangen; developments are therefore already being implemented.

- Glass melting: A test for glass melting with hydrogen instead of natural gas was successfully completed within the project. A similar burner performance at comparable temperatures as in conventional operation with natural gas and oxygen was achieved. The quality of the innovatively produced glass was also comparable to that from conventional production.

The project partners of P2X (Phase III)

All P2X and other Kopernikus publications (including the respective technical annexes of the roadmaps) are collected and searchable in this list. Below you will additionally find a selection of important information from the project.